PUWER Compliance: A Practical Guide for Safer Workplaces

Introduction

Work equipment is at the heart of almost every business, from construction sites and factories to offices and farms. But when equipment is not properly maintained or used, the consequences can be severe. The Provision and Use of Work Equipment Regulations (PUWER) were introduced to make sure employers take clear responsibility for keeping equipment safe.

For business owners and site managers, understanding PUWER isn’t just a legal obligation – it’s a way to protect staff, reduce downtime, and create a culture of safety. This blog explains what PUWER covers, the main responsibilities under the law, common compliance failures, and how digital inspection tools like workMule can make compliance simple.

What Does PUWER Cover?

One of the common misconceptions about PUWER is that it only applies to large or complex machinery. In reality, it applies to all work equipment, regardless of size or industry. That means:

-

Heavy machinery – excavators, forklifts, presses, saws, conveyor systems

-

Portable power tools – drills, grinders, nail guns, sanders

-

Vehicles – company vans, tractors, plant machinery, construction vehicles

-

Access equipment – ladders, scaffolding, mobile platforms

-

Safety devices – fire extinguishers, harnesses, guards

If equipment is used by employees at work, it is almost certainly covered by PUWER.

The Main PUWER Requirements

PUWER sets out a series of clear duties for employers and those in control of equipment. The core requirements are:

-

Suitability – equipment must be appropriate for its intended use. For example, a lightweight ladder might be fine for an office environment but unsafe on a construction site.

-

Safe condition – equipment has to be maintained so it remains safe. This includes routine servicing, repairs, and immediate action if faults are reported.

-

Inspection and testing – equipment must be inspected at suitable intervals, and higher-risk equipment may require more frequent checks.

-

Training and competence – only trained and authorised people should operate equipment. Employers must provide proper instruction and supervision.

-

Safety measures – protective devices such as guards, emergency stops, and warning systems must be in place and functional.

These requirements are not optional. Failure to comply can result in enforcement action by the Health and Safety Executive (HSE).

Who Is Responsible?

The law places responsibility on those who own, operate, or control work equipment. In practice, this usually means:

-

Employers and business owners – they hold overall accountability for PUWER compliance.

-

Managers and supervisors – they must ensure equipment is used safely on a day-to-day basis.

-

Employees – while employers carry the main duty, staff also have responsibilities to follow training, use equipment correctly, and report faults.

In short: responsibility starts at the top but must run through the whole organisation.

Why PUWER Compliance Matters

Some businesses see PUWER as another layer of red tape, but the reality is that compliance brings significant benefits:

-

Protecting staff safety – fewer accidents and injuries means a safer, healthier workforce.

-

Avoiding fines and legal action – HSE can issue improvement notices, prohibition notices, or prosecute for breaches.

-

Reducing downtime – equipment that is properly maintained is less likely to fail, meaning fewer delays to projects.

-

Improving reputation – clients, contractors, and staff are more confident working with businesses that prioritise safety.

The financial cost of an accident – both in fines and lost productivity – is often far higher than the cost of regular inspections and compliance.

Common PUWER Compliance Failures

Despite the clear regulations, many businesses still fall short. The most common failures include:

-

Missing inspection records – paper checklists are often lost, incomplete, or filled out incorrectly.

-

Faulty safety features – guards or emergency stops removed to “speed up” work.

-

Untrained staff – employees using equipment without the necessary training or authorisation.

-

Poor maintenance routines – servicing delayed until faults cause breakdowns.

-

Reactive instead of proactive checks – inspections carried out only after an accident or HSE visit.

These failures not only put workers at risk but also expose businesses to legal and financial consequences.

How workMule Supports PUWER Compliance

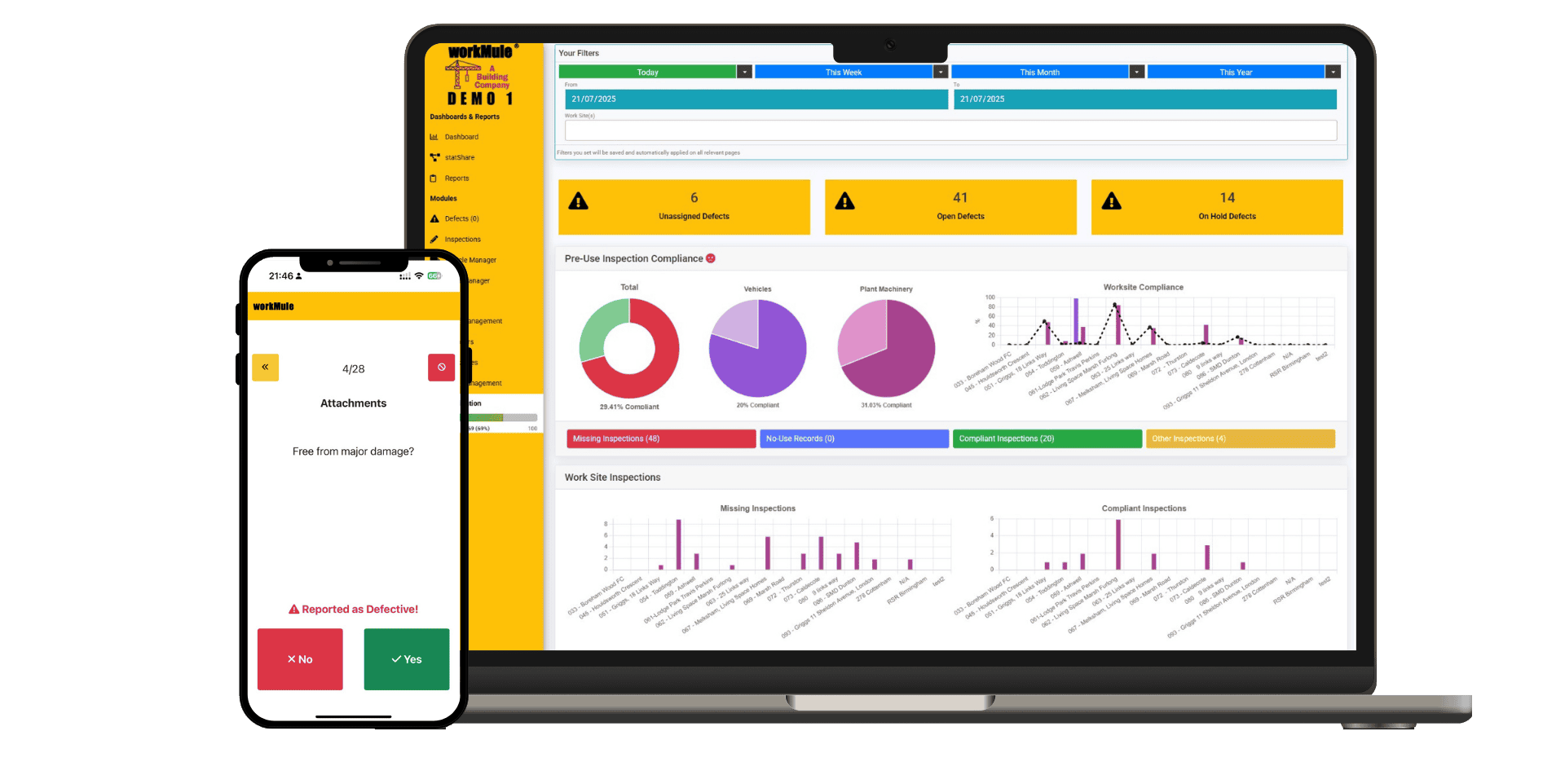

This is where digital inspection tools like workMule change the game. Instead of relying on paper trails or spreadsheets, workMule allows businesses to carry out, log, and store inspections digitally.

Key features that support PUWER compliance include:

-

Customisable digital checklists – ensure inspections meet PUWER standards and can be tailored to specific equipment.

-

Automated reminders – schedule inspections so nothing is missed.

-

Photo and video evidence – capture proof of checks, defects, or repairs in real time.

-

Instant reporting – managers can see inspection results immediately, allowing quick action on defects.

-

Secure audit trail – all inspections are stored digitally, making it easy to demonstrate compliance during HSE audits.

By moving to a digital system, businesses reduce paperwork, improve accuracy, and build a culture of accountability.

Real-World Example

Imagine a construction site with multiple excavators, drills, and scaffolding. Under PUWER, each piece of equipment must be inspected regularly. With paper records, supervisors might miss checks or fail to spot recurring faults.

Using workMule, the same site can:

-

Assign inspection tasks to staff automatically

-

Receive instant notifications when equipment fails an inspection

-

Track recurring issues across multiple sites

-

Present a complete audit history if inspected by HSE

This proactive approach not only ensures compliance but also reduces the risk of costly accidents and project delays.

Final Thoughts

PUWER is not just a legal requirement – it is a framework for safer, more efficient workplaces. Businesses that take it seriously protect their people, improve productivity, and stay ahead of compliance risks.

By switching from paper-based systems to digital inspections with workMule, companies make PUWER compliance straightforward. With automated reminders, clear records, and instant reporting, staying compliant becomes part of the daily workflow rather than a burden.