RAMS Templates: Streamline Safety Planning Across Construction Sites

Why RAMS Templates Are Essential on Construction Sites

Risk Assessment and Method Statements (RAMS) are the backbone of safety planning on any construction site. They identify hazards, establish control measures, and outline step-by-step procedures to ensure work is completed safely. Without proper RAMS, sites face higher risks of accidents, regulatory breaches, and costly downtime.

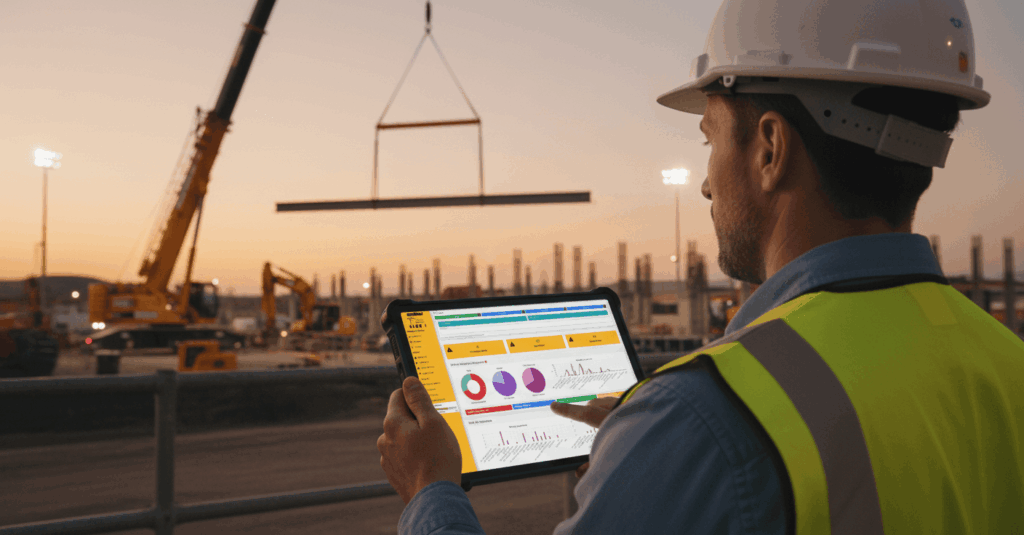

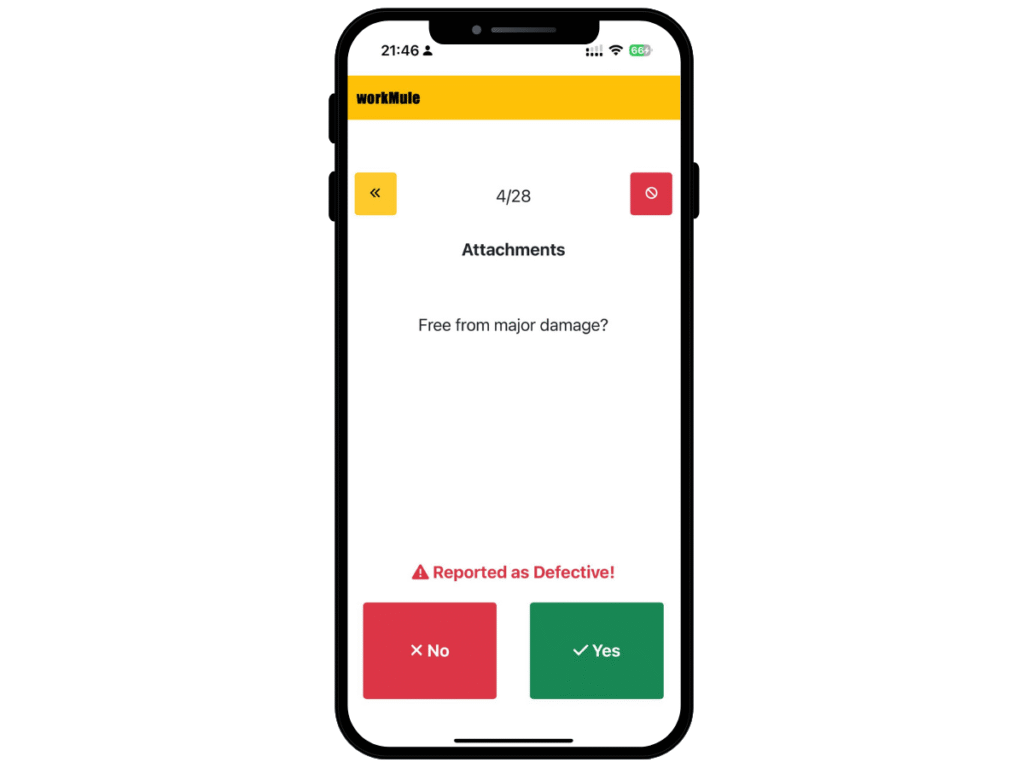

Traditionally, RAMS are drafted on paper, stored in binders, and circulated manually. This makes them vulnerable to being lost, outdated, or ignored. Digital RAMS templates offer a practical solution, giving construction teams fast, reliable, and standardised safety documentation while connecting seamlessly with other compliance tools. Platforms like workMule allow teams to replace paper with digital inspection checklists for a fully integrated safety workflow.

What a RAMS Template Covers

A typical RAMS template includes:

- Risk assessments: Identify hazards linked to specific tasks, machinery, or environmental conditions.

- Method statements: Outline step-by-step procedures for safely completing a task, including the protective measures and equipment required.

- Sign-off sections: Spaces for responsible persons to approve the plan before work begins.

- Monitoring and review: Track incidents, near misses, or adjustments to procedures.

Using digital RAMS templates ensures all critical documents are completed accurately, securely stored, and accessible instantly. They reduce the risk of human error and make it easier to monitor compliance across multiple sites. Integrating RAMS with plant inspections further ensures that machinery, equipment, and daily operational checks are aligned with safety planning.

The Benefits of Digital RAMS Templates

Switching from paper to digital RAMS templates brings measurable benefits:

- Consistency across projects: Standardised formats mean every team member follows the same process, reducing miscommunication.

- Time-saving: Digital templates can be pre-filled, duplicated, and customised for recurring tasks.

- Audit-ready: All RAMS records are centrally stored and time-stamped, making compliance checks fast and simple.

- Real-time updates: Changes to procedures or hazards propagate instantly to the workforce.

- Integration with inspections: Link RAMS directly with daily plant inspections and defect reporting to create a seamless safety workflow.

By combining RAMS with digital inspections, managers gain a holistic view of safety compliance. Every pre-use check, safety procedure, and operational task is documented and easily accessible, reducing gaps in accountability and risk oversight.

How workMule Simplifies RAMS Management

workMule is designed for construction and plant hire teams who need practical, real-time solutions to safety and compliance. The platform helps digitise RAMS templates and integrate them into day-to-day operations:

- Pre-built templates easy to customise for specific site tasks

- Offline access so teams can complete RAMS even in low-signal or remote areas

- Automated alerts and workflows linking RAMS with inspection checklists and defect reporting

- Integration with existing software via integrations for project management, maintenance, or asset tracking

- Secure storage of all RAMS documents, accessible to authorised personnel at any time

By embedding RAMS into digital workflows, safety planning becomes a live, practical tool rather than a static paper exercise. Teams can respond to new hazards, schedule reviews, and escalate issues in real time.

Best Practices for Rolling Out Digital RAMS Templates

To get the most from digital RAMS:

- Train staff on the purpose of each assessment, not just how to fill out the template.

- Connect RAMS to daily inspections and pre-use checks to create a unified safety system.

- Automate review schedules to ensure RAMS stay current with recurring hazards or regulatory changes.

- Use dashboards to monitor completion and ensure all team members sign off before work starts.

- Analyse trends and recurring issues to improve processes and prevent accidents proactively.

This approach fosters a proactive safety culture where compliance becomes an integral part of daily operations. When RAMS and inspections work together digitally, managers can quickly see which tasks or equipment pose risks and take immediate corrective action.

Tangible Benefits for Construction Teams

Implementing digital RAMS templates delivers measurable results:

- Safer worksites with fewer accidents

- Reduced administrative burden for managers and supervisors

- Faster audits and regulatory compliance checks

- Improved accountability across teams

- Enhanced integration with inspections, defect reporting, and maintenance planning

With digital RAMS and inspections linked in one platform, teams save time, reduce errors, and gain complete visibility over site safety. Real-time updates mean that everyone—from operators to managers—stays informed about potential hazards and compliance status.

Conclusion: Modernise Safety Planning with Digital RAMS

Paper-based RAMS templates slow down projects and introduce unnecessary risk. Digital RAMS through workMule streamlines safety planning, enhances compliance, and integrates seamlessly with inspections and maintenance workflows.

Every task, every assessment, and every method statement becomes traceable, actionable, and audit-ready. By making RAMS a live part of daily operations, construction teams create safer, more efficient sites where compliance is built in, not bolted on.

👉 Book a demo today to see how workMule can simplify RAMS management and help your team go fully paperless with inspections.